Elasticity

Consider an elastic plate with undeformed shape \(\Omega\times ]-h,h[\) in \(\mathbb{R}^3\), \(\Omega\subset\mathbb{R}^2\).

By the deformation of the plate, we assume that a point \(P(x_1,x_2,x_3)\) moves to \({\cal P}(\xi_1,\xi_2,\xi_3)\). The vector \(\mathbf{u}=(u_1,u_2,u_3)=(\xi_1-x_1,\xi_2-x_2,\xi_3-x_3)\) is called the displacement vector.

By the deformation, the line segment \(\overline{\mathbf{x},\mathbf{x}+\tau\Delta\mathbf{x}}\) moves approximately to \(\overline{\mathbf{x}+\mathbf{u}(\mathbf{x}),\mathbf{x}+\tau\Delta\mathbf{x} +\mathbf{u}(\mathbf{x}+\tau\Delta\mathbf{x})}\) for small \(\tau\), where \(\mathbf{x}=(x_1,x_2,x_3),\, \Delta\mathbf{x} =(\Delta x_1,\Delta x_2,\Delta x_3)\).

We now calculate the ratio between two segments:

then we have (see e.g. [NECAS2017], p.32)

where \(\nu_i=\Delta x_i|\Delta\mathbf{x}|^{-1}\). If the deformation is small, then we may consider that:

and the following is called small strain tensor:

The tensor \(e_{ij}\) is called finite strain tensor.

Consider the small plane \(\Delta \Pi(\mathbf{x})\) centered at \(\mathbf{x}\) with the unit normal direction \(\mathbf{n}=(n_1,n_2,n_3)\), then the surface on \(\Delta \Pi(\mathbf{x})\) at \(\mathbf{x}\) is:

where \(\sigma_{ij}(\mathbf{x})\) is called stress tensor at \(\mathbf{x}\). Hooke’s law is the assumption of a linear relation between \(\sigma_{ij}\) and \(\varepsilon_{ij}\) such as:

with the symmetry \(c_{ijkl}=c_{jikl}, c_{ijkl}=c_{ijlk}, c_{ijkl}=c_{klij}\).

If Hooke’s tensor \(c_{ijkl}(\mathbf{x})\) do not depend on the choice of coordinate system, the material is called isotropic at \(\mathbf{x}\).

If \(c_{ijkl}\) is constant, the material is called homogeneous. In homogeneous isotropic case, there is Lamé constants \(\lambda, \mu\) (see e.g. [NECAS2017], p.43) satisfying

where \(\delta_{ij}\) is Kronecker’s delta.

We assume that the elastic plate is fixed on \(\Gamma_D\times ]-h,h[,\, \Gamma_D\subset \partial\Omega\). If the body force \(\mathbf{f}=(f_1,f_2,f_3)\) is given in \(\Omega\times]-h,h[\) and surface force \(\mathbf{g}\) is given in \(\Gamma_N\times]-h,h[, \Gamma_N=\partial\Omega\setminus\overline{\Gamma_D}\), then the equation of equilibrium is given as follows:

We now explain the plain elasticity.

Plain strain:

On the end of plate, the contact condition \(u_3=0,\, g_3=\) is satisfied.

In this case, we can suppose that \(f_3=g_3=u_3=0\) and \(\mathbf{u}(x_1,x_2,x_3)=\overline{u}(x_1,x_2)\) for all \(-h<x_3<h\).

Plain stress:

The cylinder is assumed to be very thin and subjected to no load on the ends \(x_3=\pm h\), that is,

\[\sigma_{3i}=0,\quad x_3=\pm h,\quad i~1,2,3\]The assumption leads that \(\sigma_{3i}=0\) in \(\Omega\times ]-h,h[\) and \(\mathbf{u}(x_1,x_2,x_3)=\overline{u}(x_1,x_2)\) for all \(-h<x_3<h\).

Generalized plain stress:

The cylinder is subjected to no load at \(x_3=\pm h\). Introducing the mean values with respect to thickness,

\[\overline{u}_i(x_1,x_2)=\frac{1}{2h}\int_{-h}^h{u(x_1,x_2,x_3)dx_3}\]and we derive \(\overline{u}_3\equiv 0\). Similarly we define the mean values \(\overline{f},\overline{g}\) of the body force and surface force as well as the mean values \(\overline{\varepsilon}_{ij}\) and \(\overline{\sigma}_{ij}\) of the components of stress and strain, respectively.

In what follows we omit the overlines of \(\overline{u}, \overline{f},\overline{g}, \overline{\varepsilon}_{ij}\) and \(\overline{\varepsilon}_{ij}\). Then we obtain similar equation of equilibrium given in (58) replacing \(\Omega\times ]-h,h[\) with \(\Omega\) and changing \(i=1,2\). In the case of plane stress, \(\sigma_{ij}=\lambda^* \delta_{ij}\textrm{div}u+2\mu\varepsilon_{ij}, \lambda^*=(2\lambda \mu)/(\lambda+\mu)\).

The equations of elasticity are naturally written in variational form for the displacement vector \(\mathbf{u}(\mathbf{x})\in V\) as:

where \(V\) is the linear closed subspace of \(H^1(\Omega)^2\).

Tip

Beam

Consider an elastic plate with the undeformed rectangle shape \(]0,10[\times ]0,2[\). The body force is the gravity force \(\mathbf{f}\) and the boundary force \(\mathbf{g}\) is zero on lower and upper side. On the two vertical sides of the beam are fixed.

1// Parameters

2real E = 21.5;

3real sigma = 0.29;

4real gravity = -0.05;

5

6// Mesh

7border a(t=2, 0){x=0; y=t; label=1;}

8border b(t=0, 10){x=t; y=0; label=2;}

9border c(t=0, 2){ x=10; y=t; label=1;}

10border d(t=0, 10){ x=10-t; y=2; label=3;}

11mesh th = buildmesh(b(20) + c(5) + d(20) + a(5));

12

13// Fespace

14fespace Vh(th, [P1, P1]);

15Vh [uu, vv];

16Vh [w, s];

17

18// Macro

19real sqrt2 = sqrt(2.);

20macro epsilon(u1, u2) [dx(u1), dy(u2), (dy(u1)+dx(u2))/sqrt2] //

21macro div(u,v) (dx(u) + dy(v)) //

22

23// Problem

24real mu = E/(2*(1+sigma));

25real lambda = E*sigma/((1+sigma)*(1-2*sigma));

26solve Elasticity ([uu, vv], [w, s])

27 = int2d(th)(

28 lambda*div(w,s)*div(uu,vv)

29 + 2.*mu*( epsilon(w,s)'*epsilon(uu,vv) )

30 )

31 + int2d(th)(

32 - gravity*s

33 )

34 + on(1, uu=0, vv=0)

35;

36

37// Plot

38plot([uu, vv], wait=true);

39plot([uu,vv], wait=true, bb=[[-0.5, 2.5], [2.5, -0.5]]);

40

41// Movemesh

42mesh th1 = movemesh(th, [x+uu, y+vv]);

43plot(th1, wait=true);

Tip

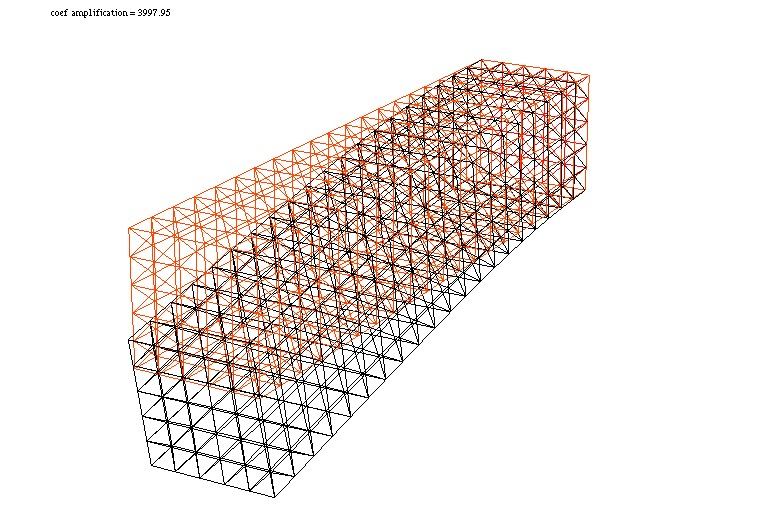

Beam 3D

Consider elastic box with the undeformed parallelepiped shape \(]0,5[\times ]0,1[\times]0,1[\). The body force is the gravity force \(\mathbf{f}\) and the boundary force \(\mathbf{g}\) is zero on all face except one the one vertical left face where the beam is fixed.

1include "cube.idp"

2

3// Parameters

4int[int] Nxyz = [20, 5, 5];

5real [int, int] Bxyz = [[0., 5.], [0., 1.], [0., 1.]];

6int [int, int] Lxyz = [[1, 2], [2, 2], [2, 2]];

7

8real E = 21.5e4;

9real sigma = 0.29;

10real gravity = -0.05;

11

12// Mesh

13mesh3 Th = Cube(Nxyz, Bxyz, Lxyz);

14

15// Fespace

16fespace Vh(Th, [P1, P1, P1]);

17Vh [u1, u2, u3], [v1, v2, v3];

18

19// Macro

20real sqrt2 = sqrt(2.);

21macro epsilon(u1, u2, u3) [

22 dx(u1), dy(u2), dz(u3),

23 (dz(u2) + dy(u3))/sqrt2,

24 (dz(u1) + dx(u3))/sqrt2,

25 (dy(u1) + dx(u2))/sqrt2] //

26macro div(u1, u2, u3) (dx(u1) + dy(u2) + dz(u3)) //

27

28// Problem

29real mu = E/(2*(1+sigma));

30real lambda = E*sigma/((1+sigma)*(1-2*sigma));

31

32solve Lame ([u1, u2, u3], [v1, v2, v3])

33 = int3d(Th)(

34 lambda*div(u1, u2, u3)*div(v1, v2, v3)

35 + 2.*mu*( epsilon(u1, u2, u3)'*epsilon(v1, v2, v3) )

36 )

37 - int3d(Th)(

38 gravity*v3

39 )

40 + on(1, u1=0, u2=0, u3=0)

41 ;

42

43// Display

44real dmax = u1[].max;

45cout << "max displacement = " << dmax << endl;

46

47// Movemesh

48real coef = 0.1/dmax;

49int[int] ref2 = [1, 0, 2, 0];

50mesh3 Thm = movemesh3(Th, transfo=[x+u1*coef, y+u2*coef, z+u3*coef], label=ref2);

51Thm = change(Thm, label=ref2);

52

53// Plot

54plot(Th, Thm, wait=true, cmm="coef amplification = "+coef);

Fracture Mechanics

Consider the plate with the crack whose undeformed shape is a curve \(\Sigma\) with the two edges \(\gamma_1,\, \gamma_2\).

We assume the stress tensor \(\sigma_{ij}\) is the state of plate stress regarding \((x,y)\in \Omega_{\Sigma}=\Omega\setminus \Sigma\). Here \(\Omega\) stands for the undeformed shape of elastic plate without crack.

If the part \(\Gamma_N\) of the boundary \(\partial\Omega\) is fixed and a load \({\cal L}=(\mathbf{f},\mathbf{g})\in L^2(\Omega)^2\times L^2(\Gamma_N)^2\) is given, then the displacement \(\mathbf{u}\) is the minimizer of the potential energy functional:

over the functional space \(V(\Omega_{\Sigma})\),

where \(w(x,\mathbf{v})=\sigma_{ij}(\mathbf{v})\varepsilon_{ij}(\mathbf{v})/2\),

If the elasticity is homogeneous isotropic, then the displacement \(\mathbf{u}(x)\) is decomposed in an open neighborhood \(U_k\) of \(\gamma_k\) as in (see e.g. [OHTSUKA2000])

with \(\mathbf{u}_{k,R} \in H^2(\Omega_\Sigma\cap U_k)^2\), where \(U_k,\, k=1,2\) are open neighborhoods of \(\gamma_k\) such that \(\partial L_1\cap U_1=\gamma_1,\, \partial L_m\cap U_2=\gamma_2\), and

where \(\mu\) is the shear modulus of elasticity, \(\kappa=3-4\nu\) (\(\nu\) is the Poisson’s ratio) for plane strain and \(\kappa=\frac {3-\nu} {1+\nu}\) for plane stress.

The coefficients \(K_1(\gamma_i)\) and \(K_2(\gamma_i),\) which are important parameters in fracture mechanics, are called stress intensity factors of the opening mode (mode I) and the sliding mode (mode II), respectively.

For simplicity, we consider the following simple crack

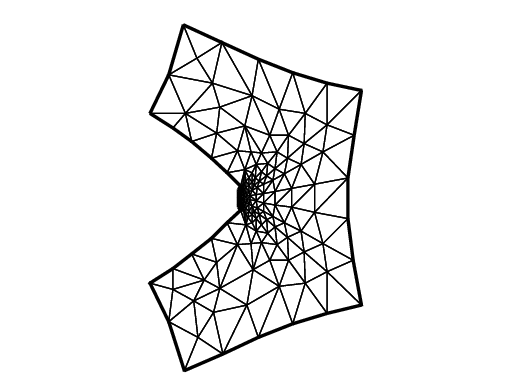

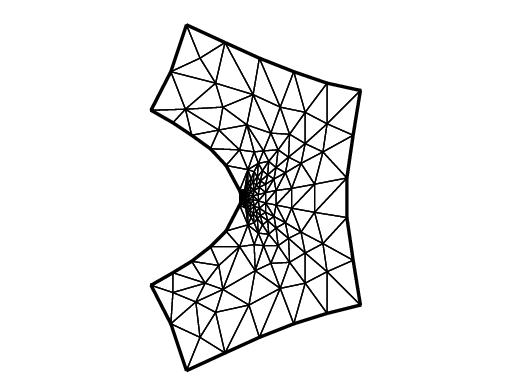

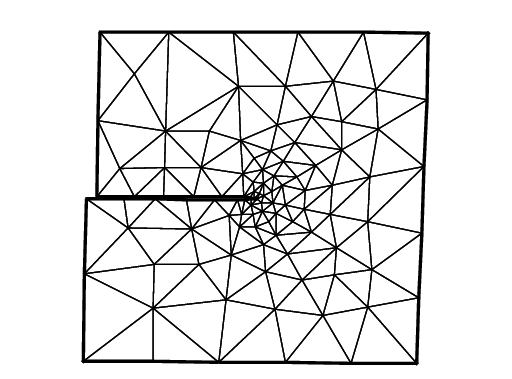

with only one crack tip \(\gamma=(0,0)\). Unfortunately, FreeFEM cannot treat crack, so we use the modification of the domain with U-shape channel (see U-shape example, Fig. 85) with \(d=0.0001\). The undeformed crack \(\Sigma\) is approximated by

and \(\Gamma_D=\)R in U-shape example, Fig. 85.

In this example, we use three technique:

Fast Finite Element Interpolator from the mesh

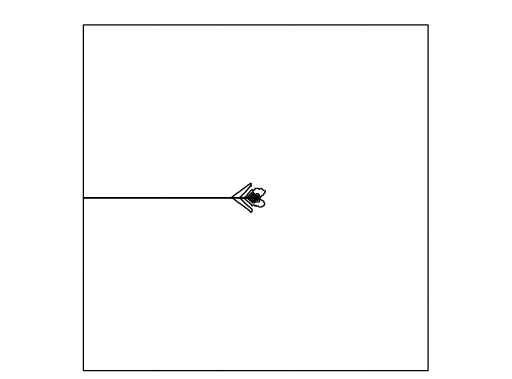

ThtoZoomfor the scale-up of near \(\gamma\).After obtaining the displacement vector \(\mathbf{u}=(u,v)\), we shall watch the deformation of the crack near \(\gamma\) as follows,

1mesh Plate = movemesh(Zoom, [x+u, y+v]); 2plot(Plate);

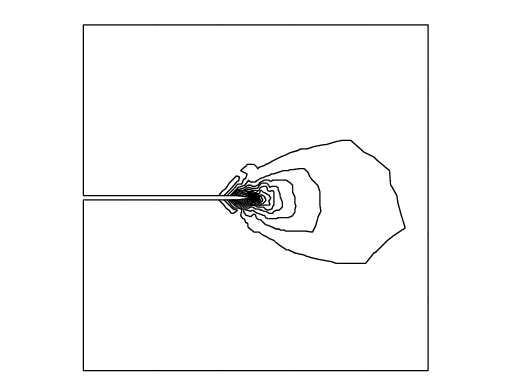

Adaptivity is an important technique here, because a large singularity occurs at \(\gamma\) as shown in (59).

The first example creates mode I deformation by the opposed surface force on B and T in the vertical direction of \(\Sigma\), and the displacement is fixed on R.

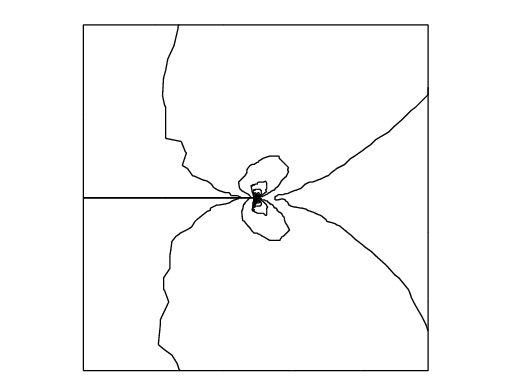

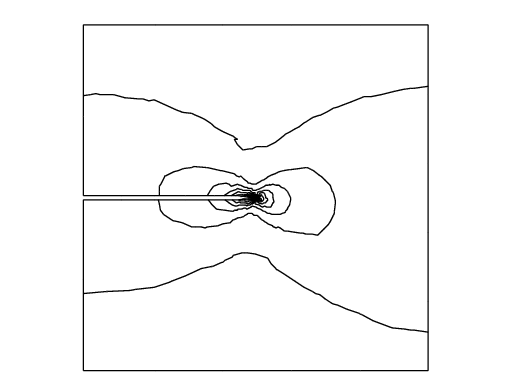

In a laboratory, fracture engineers use photoelasticity to make stress field visible, which shows the principal stress difference

where \(\sigma_1\) and \(\sigma_2\) are the principal stresses.

In opening mode, the photoelasticity make symmetric pattern concentrated at \(\gamma\).

Tip

Crack Opening, \(K_2(\gamma)=0\)

1//Parameters

2real d = 0.0001; int n = 5; real cb = 1, ca = 1, tip = 0.0;

3

4real E = 21.5;

5real sigma = 0.29;

6

7// Mesh

8border L1(t=0, ca-d){x=-cb; y=-d-t;}

9border L2(t=0, ca-d){x=-cb; y=ca-t;}

10border B(t=0, 2){x=cb*(t-1); y=-ca;}

11border C1(t=0, 1){x=-ca*(1-t)+(tip-10*d)*t; y=d;}

12border C21(t=0, 1){x=(tip-10*d)*(1-t)+tip*t; y=d*(1-t);}

13border C22(t=0, 1){x=(tip-10*d)*t+tip*(1-t); y=-d*t;}

14border C3(t=0, 1){x=(tip-10*d)*(1-t)-ca*t; y=-d;}

15border C4(t=0, 2*d){x=-ca; y=-d+t;}

16border R(t=0, 2){x=cb; y=cb*(t-1);}

17border T(t=0, 2){x=cb*(1-t); y=ca;}

18mesh Th = buildmesh(L1(n/2) + L2(n/2) + B(n)

19 + C1(n) + C21(3) + C22(3) + C3(n) + R(n) + T(n));

20plot(Th, wait=true);

21

22cb=0.1; ca=0.1;

23mesh Zoom = buildmesh(L1(n/2) + L2(n/2) + B(n) + C1(n)

24 + C21(3) + C22(3) + C3(n) + R(n) + T(n));

25plot(Zoom, wait=true);

26

27// Fespace

28fespace Vh(Th, [P2, P2]);

29Vh [u, v];

30Vh [w, s];

31

32fespace zVh(Zoom, P2);

33zVh Sx, Sy, Sxy, N;

34

35// Problem

36real mu = E/(2*(1+sigma));

37real lambda = E*sigma/((1+sigma)*(1-2*sigma));

38solve Problem ([u, v], [w, s])

39 = int2d(Th)(

40 2*mu*(dx(u)*dx(w) + ((dx(v)+dy(u))*(dx(s)+dy(w)))/4)

41 + lambda*(dx(u) + dy(v))*(dx(w) + dy(s))/2

42 )

43 -int1d(Th, T)(

44 0.1*(1-x)*s

45 )

46 +int1d(Th, B)(

47 0.1*(1-x)*s

48 )

49 +on(R, u=0, v=0)

50 ;

51

52// Loop

53for (int i = 1; i <= 5; i++){

54 mesh Plate = movemesh(Zoom, [x+u, y+v]); //deformation near gamma

55 Sx = lambda*(dx(u) + dy(v)) + 2*mu*dx(u);

56 Sy = lambda*(dx(u) + dy(v)) + 2*mu*dy(v);

57 Sxy = mu*(dy(u) + dx(v));

58 N = 0.1*1*sqrt((Sx-Sy)^2 + 4*Sxy^2); //principal stress difference

59 if (i == 1){

60 plot(Plate, bw=1);

61 plot(N, bw=1);

62 }

63 else if (i == 5){

64 plot(Plate, bw=1);

65 plot(N, bw=1);

66 break;

67 }

68

69 // Adaptmesh

70 Th = adaptmesh(Th, [u, v]);

71

72 // Solve

73 Problem;

74}

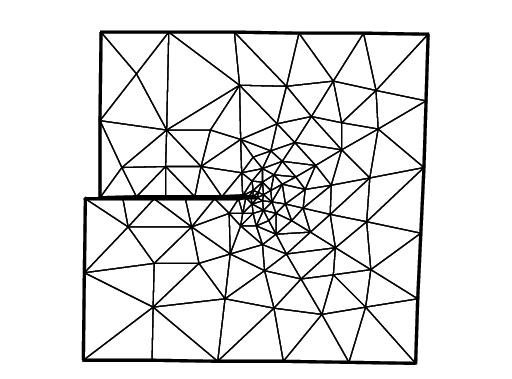

It is difficult to create mode II deformation by the opposed shear force on B and T that is observed in a laboratory.

So we use the body shear force along \(\Sigma\), that is, the \(x\)-component \(f_1\) of the body force \(\mathbf{f}\) is given by

where \(H(t)=1\) if \(t>0\); \(= 0\) if \(t<0\).

Tip

Crack Sliding, \(K_2(\gamma)=0\)

1// Parameters

2real d = 0.0001; int n = 5; real cb = 1, ca = 1, tip = 0.0;

3

4real E = 21.5;

5real sigma = 0.29;

6

7// Mesh

8border L1(t=0, ca-d){x=-cb; y=-d-t;}

9border L2(t=0, ca-d){x=-cb; y=ca-t;}

10border B(t=0, 2){x=cb*(t-1); y=-ca;}

11border C1(t=0, 1){x=-ca*(1-t)+(tip-10*d)*t; y=d;}

12border C21(t=0, 1){x=(tip-10*d)*(1-t)+tip*t; y=d*(1-t);}

13border C22(t=0, 1){x=(tip-10*d)*t+tip*(1-t); y=-d*t;}

14border C3(t=0, 1){x=(tip-10*d)*(1-t)-ca*t; y=-d;}

15border C4(t=0, 2*d){x=-ca; y=-d+t;}

16border R(t=0, 2){x=cb; y=cb*(t-1);}

17border T(t=0, 2){x=cb*(1-t); y=ca;}

18mesh Th = buildmesh(L1(n/2) + L2(n/2) + B(n)

19 + C1(n) + C21(3) + C22(3) + C3(n) + R(n) + T(n));

20plot(Th, wait=true);

21

22cb=0.1; ca=0.1;

23mesh Zoom = buildmesh(L1(n/2) + L2(n/2) + B(n) + C1(n)

24 + C21(3) + C22(3) + C3(n) + R(n) + T(n));

25plot(Zoom, wait=true);

26

27// Fespace

28fespace Vh(Th, [P2, P2]);

29Vh [u, v];

30Vh [w, s];

31

32fespace zVh(Zoom, P2);

33zVh Sx, Sy, Sxy, N;

34

35fespace Vh1(Th,P1);

36Vh1 fx = ((y>0.001)*(y<0.1))-((y<-0.001)*(y>-0.1));

37

38// Problem

39real mu = E/(2*(1+sigma));

40real lambda = E*sigma/((1+sigma)*(1-2*sigma));

41solve Problem ([u, v], [w, s])

42 = int2d(Th)(

43 2*mu*(dx(u)*dx(w) + ((dx(v) + dy(u))*(dx(s)+ dy(w)))/4)

44 + lambda*(dx(u) + dy(v))*(dx(w) + dy(s))/2

45 )

46 -int2d(Th)(

47 fx*w

48 )

49 +on(R, u=0, v=0)

50 ;

51

52// Loop

53for (int i = 1; i <= 3; i++){

54 mesh Plate = movemesh(Zoom, [x+u, y+v]); //deformation near gamma

55 Sx = lambda*(dx(u) + dy(v)) + 2*mu*dx(u);

56 Sy = lambda*(dx(u) + dy(v)) + 2*mu*dy(v);

57 Sxy = mu*(dy(u) + dx(v));

58 N = 0.1*1*sqrt((Sx-Sy)^2 + 4*Sxy^2); //principal stress difference

59 if (i == 1){

60 plot(Plate, bw=1);

61 plot(N, bw=1);

62 }

63 else if (i == 3) {

64 plot(Plate, bw=1);

65 plot(N, bw=1);

66 break;

67 }

68

69 // Adaptmesh

70 Th=adaptmesh(Th, [u, v]);

71

72 // Solve

73 Problem;

74}